- +91-9821095533

- [email protected]

- Plot No. 64, 1'st Cross Street, Darukhana, Reay Road, Mumbai- 400010

Testing and Inspection

Testing and Inspection

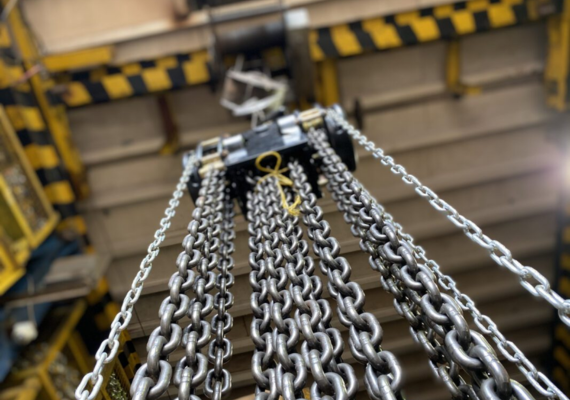

If your business is in the heavy-lifting industry then you will know just how important the quality of your equipment is, not just for the safety of your employees and the protection of your assets but also for meeting industry regulations.

Horizontal Test Beds

Our in house load test bed is capable for testing upto 1000 metric tonnes. All our test beds are approved by IRS (Indian register of shipping) , DGFASLI (Directorate General, Factory Advice and Labour Institutes) and Directorate of industrial safety and health

Class Approval Testing

Jebrahim is well associated with multiple inspection bodies to conduct material inspection at our works. We have the infrastructure and years of relationship with inspection bodies to successfully conduct various types of test

Onsite Inspection

We have the required certification equipment to conduct inspection now on site. Jebrahim can either carry our visual inspection of the material, load testing and other forms inspection on site

Horizontal Load Testing

Horizontal load testing is a critical process for evaluating the strength, stability, and load capacity of lifting products such as slings, shackles, and hooks. Testing is carried out according to international standards and involves applying a horizontal force using hydraulic or other equipment. During testing, strain gauges and other instruments measure the deflection, strain, and other parameters of the product. The results of the testing determine whether the product meets the required safety standards and load capacity. Products that pass the test are marked with relevant information, and manufacturers and users can have confidence in the performance of these products, reducing the risk of accidents and injuries.

Vertical Load Testing

Vertical load testing is a crucial evaluation process that assesses the strength and safety of lifting equipment. It involves subjecting cranes, hoists, and lifting slings to progressively increasing loads beyond their rated capacities to ensure structural integrity. Safety measures are in place to protect personnel and structures during the test. Engineers monitor the equipment for stress, deformation, and weaknesses using strain gauges and load cells. Data analysis compares results with industry standards and regulations. Successful testing leads to certification, confirming the equipment’s safety and suitability for specified loads. This process prevents accidents and downtime, ensuring reliable and secure lifting operations.